Two Stage Compounding Extruder for PVC Cable Material

Product description

Definition:

PVC cable materials are special pellets that based on PVC resin, added calcium carbonate and other inorganic filler, plasticizers, additives, lubricant additives, etc, after mixing, compounding and extrusion.

Characteristics of product:

1. High resistance to breakdown strength

2. Low dielectric loss

3. Good and stable insulation

4. Good softness

5. Good mechanical properties and electric properties

6. Strong acid and alkali resistance, good chemical stability

Application:

it is suitable for thin plate, wire and cable insulation, seal, etc.

Production line:

Introduction of ATS two-stage compounding line

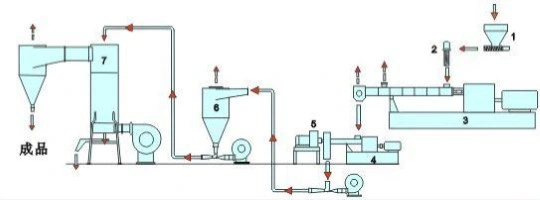

To produce PVC cable materials, we generally use ATS two-stage compounding line. ATS Two-stage compounding line includes ATE Twin screw extruder, ASE Single screw extruder and down-stream pelletizing system. The first stage is to realize the polymers compounding job, second stage is to extrude the compounds with gentle and lower temperature, then pelletizing through the down-stream cutting system.

About the pelletizing system

Multiple cutting systems also can be adopted in the ATS compounding line. Thanks to the modular design principle, both Instrument control and PLC control are also available to be applied in the ATS electrical controlling system. All the key electrical parts adopt European brands to guarantee the controlling system with significant and stable performance.

To produce PVC cable materials, we usually use the pelletizing system: air-cooling die-face hot cutting. It has the advantage: combine high-speech and strong-compounding of twin-screw extruder with low-speech, low-temperature and weak-shear of single-screw extruder. It is the first choice when produce heat-sensitive or shear-sensitive material.

Production process

1. Measuring feeding machine

2. First stage: twin screw extruder

3. Second stage: single screw extruder

4. Air-cooling die-face hot cutting

5. Cyclone separator

6. Air cooling extended vibrating screen

7. Metering packaging weigher

Main technical specification:

| Machine size | Screw Diameter (mm) | Screw Speed Max. (rpm) | Motor Power (Kw) | Throughput Rate (Kg/h) | |

| ATS52/120 | ATE52 | 51.4 | 600 | 55 | 150-300 |

| ASE120 | 120 | 85 | 37 | ||

| ATS65/150 | ATE52 | 62.4 | 600 | 90 | 300-500 |

| ASE150 | 150 | 85 | 45 | ||

| ATS75/180 | ATE75 | 71 | 600 | 132 | 500-800 |

| ASE180 | 180 | 85 | 55 | ||

| ATS95/200 | ATE95 | 93 | 600 | 250 | 800-1500 |

| ASE200 | 200 | 85 | 75 | ||

Characteristics of this set of equipment:

1. Good mixing effect and the temperature control is convenient

2. Covers a small area and doesn't need large electricity

3. Raw material mixing and granulating are entirely automatic, human demand is small

4. High-safety and can reduce raw materials' damage and deterioration

About our service:

PVC Cable Extruder Before-sale

1. Introduce products and applications detain

2. Recommend suitable solution

3. Provide with reference information

4. Offer lab for test

During Manufacturing

1. Provide with layout and engineering conditions

2. Inform the project processing status

3. Offer other documents

After-sale

1. Provide with installation, commissioning and training

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

Why choose us:

1. Lower investment cost for a high quality and durable machine;

2. Low energy consumption with high production output;

3. Overseas installation and training are available;

4. Machine warranty with spares in stocking and in-time delivery;

5. Fast machine delivery and installation: AceRetech produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an AceRetech recycling machine is 60 days.