We make all kinds of roots blower, centrifugal blower, Our Main products are as below:

The working principle of the three-blade roots blower: two three-lobed rotors are arranged in the cavity, and the

suction port and the discharge port are opened on both sides of the cavity. Through the action of a pair of

synchronous gears, the two rotors rotate in opposite directions and Relying on the mutual engagement of the two

rotors, the suction port and the discharge port are isolated, and the gas in the chamber is pushed to achieve the

purpose of blowing.

Feature of our roots blower:

1. Large adjustment of the air volume

2. Low Noise

3. High efficiency

4. Low energy cosumption

5. Long time life

6. Reliable running, easy maintenance,small footprint

The parameters of our roots blower:

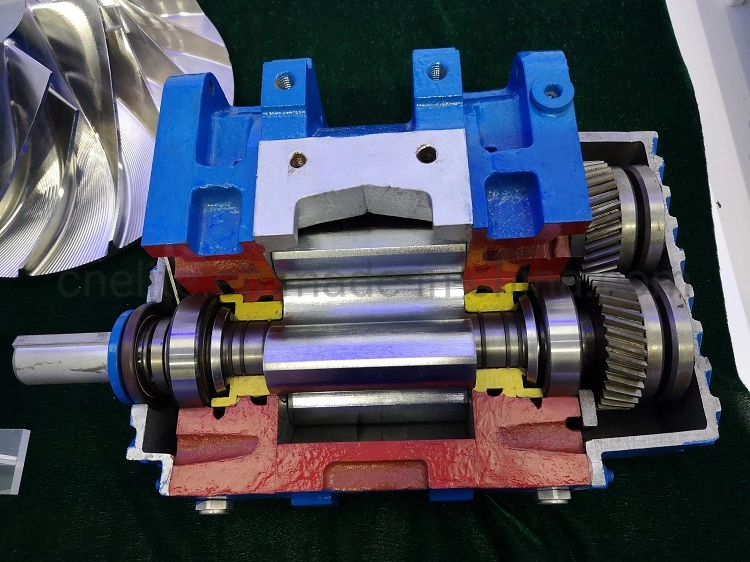

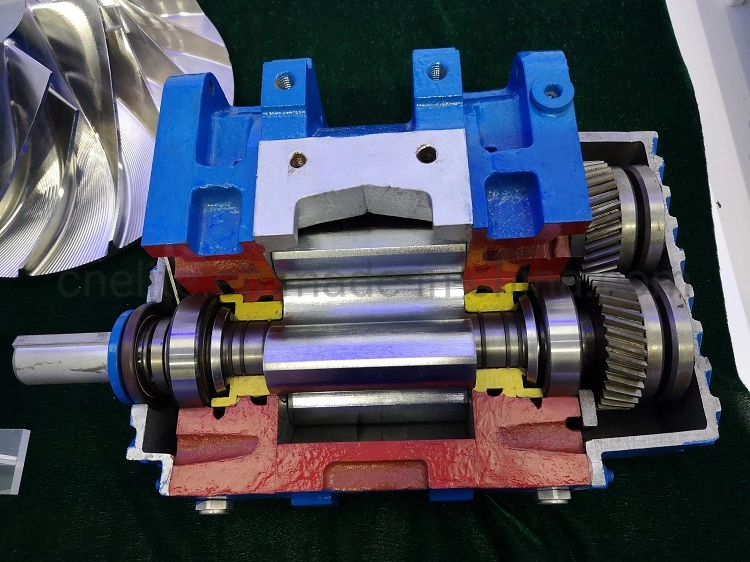

Spare parts and structure of our roots blower:

Package of our Roots Blower

Pack into iron case, two layer,blower body and motor in lower layer, inlet/out silencer etc in upper layer

Roots blower pack method same as iron case, just change to Fumigation Free Plywood Case

Our factory is a professional manufacturer of Roots blowers which has over 20 years' experience in machinery

manufacturing. It is located in Zhangqiu East Industrial Park, 50 kilometers to the east of Shandong provincial

capital--- Jinan. Our company also has convenient traffic transportation, as it is 15 kilometers away from

Diaozhen Town station of Qingdao-yinchuan expressway, and 30 kilometers away from East Jinan station of

Beijing-shanghai expressway.The leading product of our company is ESR -type Roots Blower. The roots

vacuum pump is a new type of high-efficiency roots blower, which is developed independently based on the

domestic and foreign advanced technologies. Several patented technologies have been adopted on Roots

Blower, and thus we have made significant effects in energy conservation and noise reduction, etc.. So far, our

company has invested more than 30,000,000 RMB to introduce such advanced professional equipment as

horizontal machining center, vertical machining center, two-way CNC surface planer, CNC lathe, CNC milling

machine, CNC planer, plane grinder, cylindrical grinding machine, and three coordinates testing machine.

Besides, we have taken various measures to standardize the process flow such as working and cooperating

with many scientific research units, colleges and universities at home and abroad. We also continuously try to

absorb and improve the domestic advanced production technologies, so as to promote the upgrading and

optimization of the product and make the product quality reach the advanced level at home and abroad.

ESR -type Roots Blower includes several series such as Three-leaves Type, Two-leaves Type and Centrifugal

Type,which can be further divided to hundreds of varieties. The products are widely used in sewage treatment,

pneumatic conveying,vacuum packaging, aquaculture, food processing, electric power, petrochemical, cement,

mining and other industries. Our products have such advantages as low noise, energy saving, stable quality,

and long service life, etc.. With the sales outlets throughout the domestic capital cities, our products sell well all

over the country, and have been exported to North America,Russia, Malaysia, Indonesia, Vietnam, South Africa

and some other countries. Having got the ISO9001 International Quality System Certification, we have

established and improved the quality assurance of the products designing, manufacturing, and installation.

From the process of design, research and development to the finished products, we have got the whole

process controlled independently, thus providing the full basis and reliability guarantee for the products stability

and durability. Having a perfect sales network and after-sales service, we provide our customers with higher-

quality and more efficient service.All staff of our company sincerely welcome the broad masses of friends to

guide, and negotiate business with us.

Our Roots Blower Workshop

Doosn Horzitonal Machine Center

The Application of the Roots Blower

Maintenance and inspection

(1) Check all fasteners and locating pins conditions whether they are loosening.

(2) Always check whether the leakage phenomenon of the body.

(3) Pay attention to lubrication, amount of grease and noises when running,

determine whether it works under the required conditions.

(4) Lubricant & grease: The lubricant is for medium load industrial gear oil

(grade 220, kinematic viscosity of 198 ~ 242mm2 / s 40ºC, flash point ≥ 200ºC);

The grease is butter (synthetic lithium grease penetration 220-250, drop point ≥

190ºC). Replace the lubricant and grease after first 200 hours running, and replace

again after a moth running. Later, replace the lubricant and grease according to the

environment and lubricant (grease) quality; propose a suitable replacement for three

months.

(5) Always check the inlet air filter, clean or replace the filter in time.

(6) Blower overload sometimes not immediately displayed, so pay attention to

the intake and exhaust pressure, bearing temperature and the current increase trends

of motor to determine whether the blower works normally;

(7) Before disassembling the blower, the assembling relation and dimensions

must be recorded or measured, make marks on components to ensure the original

requirements after assembling.

(8) When newly machine or overhaul, the oil tank should be cleaned before use

and propose replace all grease after 8 hours running.

Common failure reason and troubleshooting

Our Service

1. Pre sell service 2. After sell service

a. recommend the suitable model c. online technical support,

b. factory tour d. whole life spare parts and techinical support

Gurantee

12 months gurantee for our roots blowers

| Type | Diameter | Rate of flow | Pressure |

| ESR-MJ(Intensive Type) | Φ50~Φ300mm | 0.5~140m³/min | 9.8KPa~98.8Kpa |

| ESR(Ordinary Type) | Φ50~Φ350mm | 0.5~140m³/min | 9.8KPa~78.4Kpa |

| ESR-H(High-pressure Type) | Φ50~Φ350mm | 0.7~160m³/min | 58.8KPa~98.8Kpa |

| ESR-V(Vacuum Pump) | Φ50~Φ350mm | 0.5~160m³/min | 9.8KPa~53.3Kpa |

| EL Series | Φ200~Φ600mm | 20.3~750m³/min | 9.8KPa~58.8Kpa |

| Multistage Centrifugal Blower or C-Series | Φ250~Φ500mm | 50~500m³/min | 9.8KPa~98Kpa |

| ERR-ERG Type | Φ250~Φ500mm | 120~420m³/min | 9.8KPa~98.8Kpa |

The working principle of the three-blade roots blower: two three-lobed rotors are arranged in the cavity, and the

suction port and the discharge port are opened on both sides of the cavity. Through the action of a pair of

synchronous gears, the two rotors rotate in opposite directions and Relying on the mutual engagement of the two

rotors, the suction port and the discharge port are isolated, and the gas in the chamber is pushed to achieve the

purpose of blowing.

Feature of our roots blower:

1. Large adjustment of the air volume

2. Low Noise

3. High efficiency

4. Low energy cosumption

5. Long time life

6. Reliable running, easy maintenance,small footprint

The parameters of our roots blower:

| Type | Ratary Speed (r/min) | Pressure Rise (Kpa) | Capacity (m/min) | Shaft Power (Kw) | Motor | Unit Maximn Weight(Kg) |

| Power (Kw) | ||||||

| ESR-50 | 1100-2120 | 9.8-58.8 | 0.65-2.58 | 0.3-3.54 | 0.75-4 | 128-158 |

| ESR-65 | 1100-2130 | 9.8-58.8 | 0.94-3.66 | 0.38-4.46 | 0.75-5.5 | 155-185 |

| ESR-80 | 1140-1900 | 9.8-58.8 | 2.34-5.43 | 1.04-7.42 | 2.2-11 | 155-277 |

| ESR-100 | 1060-1980 | 9.8-58.8 | 4.57-9.05 | 1.35-12.15 | 3-15 | 309-377 |

| ESR-125 | 980-1850 | 9.8-58.8 | 5.35-12.4 | 1.65-5.19 | 5.5-18.5 | 408-451 |

| ESR-125C | 970-1830 | 9.8-58.8 | 7.5-17.57 | 3.2-18.5 | 4-22 | 408-451 |

| ESR-150 | 810-1730 | 9.8-58.8 | 10.37-27.15 | 3.84-40.82 | 7.5-45 | 688-848 |

| ESR-175 | 970-1520 | 9.8-58.8 | 19.65-36.65 | 7.2-45.95 | 11-55 | 980-1080 |

| ESR-200B | 740-1450 | 9.8-58.8 | 19.65-44.8 | 10.15-60.44 | 15-75 | 1272-1546 |

| ESR-200 | 810-1480 | 9.8-58.8 | 27.65-59.2 | 8.05-80,12 | 15-90 | 1272-1546 |

| ESR-250B | 1100-1480 | 9.8-58.8 | 54.77-77.55 | 19.97-90.97 | 30-110 | 1490-2454 |

| ESR-250 | 990-1480 | 9.8-58.8 | 61.4-97.52 | 20.1-117.3 | 30-132 | 1490-2454 |

| ESR-300 | 990-1480 | 9.8-58.8 | 87.1-138.1 | 26.4-167.8 | 37-185 | 3326-3446 |

| ESR-350 | 730-1480 | 9.8-58.8 | 78.41-177.31 | 55-250 | ||

| ESR-50H | 1230-2120 | 63.7-98 | 0.45-2.02 | 2.05-6.12 | 3-7.5 | 160--170 |

| ESR-65H | 1240-2130 | 63.7-98 | 0.78-2.53 | 2.89-7.55 | 4-11 | 198-230 |

| ESR-80H | 1140-1900 | 63.7-98 | 1.82-4.55 | 4.09-10.1 | 5.5-15 | 316-326 |

| ESR-100H | 1060-1980 | 63.7-98 | 2.65-8.06 | 6.36-17.2 | 7.5-22 | 398-459 |

| ESR-125H | 980-1850 | 63.7-98 | 4.64-11.23 | 8.92-24.2 | 11-30 | 544-630 |

| ESR-150H | 810-1730 | 63.7-98 | 9.53-25.76 | 17.16-65 | 18.5-75 | 752-1020 |

| ESR-200H | 810-1480 | 63.7-98 | 25.34-56.92 | 42.34-120 | 55-132 | 1426-1934 |

| ESR-250H | 990-1480 | 63.7-98 | 58-93.7 | 83.2-205 | 90-220 | 2980-3468 |

| ESR300H | 990-1480 | 63.7-98 | 86.9-134.1 | 114.7-270 | 132-280 | 3476-3998 |

| ERF-245 | 650-980 | 9.8-98 | 47.5-97.4 | 16-183 | 18.5-200 | 3630-3690 |

| ERF-250 | 650-980 | 9.8-98 | 61.6-120.4 | 19-227 | 22-250 | 4450-4500 |

| ERF-290 | 650-980 | 9.8-78.4 | 92.3-128 | 22-213 | 30-250 | 4890-4710 |

| ERF-295 | 650-980 | 9.8-78.4 | 97.3-152.5 | 23-227 | 30-250 | 4890-4880 |

| ERF-297 | 650-980 | 9.8-78.4 | 87.5-167.6 | 26-249 | 30-280 | 5330-5520 |

| ERF-300 | 650-980 | 9.8-78.4 | 101.5-188.7 | 29-278 | 37-315 | 5330-5520 |

| ERF-350 | 650-980 | 9.8-78.4 | 126-224.9 | 34-249 | 45-280 | 5210-6470 |

| ERG-300 | 590-730 | 9.8-98 | 128.3-196 | 38-362 | 45-400 | 9440-10100 |

| ERG-350 | 590-730 | 9.8-98 | 159.3-231.6 | 43-420 | 55-450 | 9700-10750 |

| ERG-400 | 590-730 | 9.8-83.3 | 203.1-290.9 | 52-449 | 75-500 | 10090-11390 |

| ERG-445 | 590-730 | 9.8-73.5 | 229.7-327.8 | 58-477 | 75-560 | 10600-12230 |

| ERG-450 | 590-730 | 9.8-73.5 | 262.4-366.2 | 64-496 | 75-560 | 10600-12230 |

| ERG-500 | 590-730 | 9.8-63.7 | 327.4-452.4 | 78-529 | 90-560 | 12790-14620 |

| ERF-240-V | 650-980 | -9.8- -49 | 38.1-78 | 13-76 | 18.5-90 | 3420-3285 |

| ERF-245-V | 650-980 | -9.8- -49 | 47.5-97.4 | 16-95 | 22-110 | 3425-3360 |

| ERF-250-V | 650-980 | -9.8- -49 | 63-120 | 19-117 | 22-132 | 3910-3830 |

| ERF-290-V | 650-980 | -9.8- -49 | 72.6-144 | 22-136 | 30-160 | 4415-4270 |

| ERF-295-V | 650-980 | -9.8- -49 | 76.6-152 | 23-145 | 30-160 | 4425-4485 |

| ERF-297-V | 650-980 | -9.8- -49 | 84.3-166.8 | 26-160 | 30-180 | 5000-4980 |

| ERF-300-V | 650-980 | -9.8- -49 | 97-192 | 29-178 | 37-200 | 5000-4980 |

| ERF-350-V | 650-980 | -9.8- -49 | 116-225 | 34-209 | 45-250 | 5400-5700 |

| ERG-300V | 590-730 | -9.8- -49 | 133-193 | 38-184 | 45-220 | 7800-9100 |

| ERG-350V | 590-730 | -9.8- -49 | 163-231 | 43-216 | 55-250 | 9500-9470 |

| ERG-400V | 590-730 | -9.8- -49 | 199-290 | 52-269 | 75-315 | 9900-10130 |

| ERG-445V | 590-730 | -9.8- -49 | 224.8-326.9 | 58-303 | 75-355 | 9900-10130 |

| ERG-450V | 590-730 | -9.8- -49 | 255-365 | 64-335 | 75-400 | 11230-11300 |

| ERG-500V | 590-730 | -9.8- -49 | 314-452 | 78-412 | 132-450 | 13630-13850 |

| ERF-245W | 650-980 | -13.3- -53.3 | 53.5-101 | 21.5-102 | 30-110 | 3630-3360 |

| ERF-250W | 650-980 | -13.3- -53.3 | 69-127 | 26.5-127 | 30-160 | 3985-4115 |

| ERF-290W | 650-980 | -13.3- -53.3 | 82.6-150 | 30.5-149 | 37-185 | 4340-4580 |

| ERF-295W | 650-980 | -13.3- -53.3 | 87-158 | 32-158 | 37-185 | 4440-4580 |

| ERF-297W | 650-980 | -13.3- -53.3 | 95-174 | 36-174 | 45-200 | 5230-5130 |

| ERF-300W | 650-980 | -13.3- -53.3 | 109-195 | 40-193 | 55-220 | 5230-5130 |

| ERF-350W | 650-980 | -13.3- -53.3 | 129-230 | 50-230 | 75-250 | 5840-5670 |

| ERG-300W | 590-730 | -13.3- -53.3 | 142-197 | 52-201 | 75-220 | 9100-9000 |

| ERF-350W | 590-730 | -13.3- -53.3 | 168-234.4 | 59-235.5 | 75-280 | 9500-9600 |

| ERG-400W | 590-730 | -13.3- -53.3 | 220-276.6 | 71-292 | 90-315 | 9900-10130 |

| ERG-445W | 590-730 | -13.3- -53.3 | 244-294.6 | 82-331 | 90-400 | 11230-11300 |

| ERG450W | 590-730 | -13.3- -53.3 | 275-368.5 | 91-366 | 110-400 | 11230-11300 |

| ETRF-250 (240,250) | 650-980 | 98-196 | 64.8-112 | 135-355 | 160-400 | 8700-8600 |

| ETRF-295 (245,295) | 650-980 | 98-196 | 80.8-139 | 167-439 | 185-500 | 9200-9100 |

| ETRF-300 (245,295) | 650-980 | 98-176.4 | 102-174 | 206-497 | 250-560 | 10320-10500 |

| ETRF-350 (245,295) | 650-980 | 98-137.2 | 124-207 | 241-473 | 280-560 | 10700-11110 |

| ETRG-400 (300,400) | 590-740 | 98-176.4 | 205-273 | 380-773 | 450-900 | 21350-24200 |

| ETRG-450 (350,450) | 590-740 | 98-176.4 | 263-428 | 476-955 | 560-1000 | 24200-27600 |

| ETRF-250W (240,250) | 650-980 | -53.3--80 | 72-121 | 75.6-121 | 90-160 | 6100-6470 |

| ETRF-295W (245/295) | 650-980 | -53.3--80 | 93.8-154 | 99.5-186 | 110-220 | 7000-6400 |

| ETRF-300W (2505/300) | 650-980 | -53.3--80 | 116-189 | 115-220 | 132-250 | 7750-7760 |

| EL81WD | 580-980 | 9.8-58.8 | 54.2-130 | 18-151 | 45-185 | 3595 |

| EL82WDB | 580-980 | 9.8-58.8 | 72.8-161 | 22-191 | 45-220 | 3860 |

| EL83WDA | 580-980 | 9.8-58.9 | 101-213 | 28.5-202 | 45-220 | 4300 |

| EL84WDA | 580-980 | 9.8-58.8 | 129-267 | 35.4-252 | 45-280 | 4720 |

| EL93WDA | 580-730 | 9.8-49 | 230-329 | 56.4-311 | 75-355 | 7765 |

| EL94WDA | 580-730 | 9.8-49 | 263-373 | 64-353 | 75-400 | 8130 |

| EL95WDA | 490-580 | 9.8-58.8 | 308-434 | 81.4-414 | 90-450 | 11500 |

| EL96WDA | 580 | 58.8 | 381 | 497 | 560 | 11500 |

| E397WN | 1000-1650 | 40 | 5-9 | |||

| E408WN | 870-1650 | 40 | 10-22 | |||

| E517WN | 980-1580 | 40 | 20-30 | |||

| E520WN | 930-1550 | 40 | 24-45 | |||

| E607WN | 750-1250 | 40 | 45-76 | |||

| E610WN | 750-1250 | 40 | 75-130 |

Package of our Roots Blower

Pack into iron case, two layer,blower body and motor in lower layer, inlet/out silencer etc in upper layer

Roots blower pack method same as iron case, just change to Fumigation Free Plywood Case

Our factory is a professional manufacturer of Roots blowers which has over 20 years' experience in machinery

manufacturing. It is located in Zhangqiu East Industrial Park, 50 kilometers to the east of Shandong provincial

capital--- Jinan. Our company also has convenient traffic transportation, as it is 15 kilometers away from

Diaozhen Town station of Qingdao-yinchuan expressway, and 30 kilometers away from East Jinan station of

Beijing-shanghai expressway.The leading product of our company is ESR -type Roots Blower. The roots

vacuum pump is a new type of high-efficiency roots blower, which is developed independently based on the

domestic and foreign advanced technologies. Several patented technologies have been adopted on Roots

Blower, and thus we have made significant effects in energy conservation and noise reduction, etc.. So far, our

company has invested more than 30,000,000 RMB to introduce such advanced professional equipment as

horizontal machining center, vertical machining center, two-way CNC surface planer, CNC lathe, CNC milling

machine, CNC planer, plane grinder, cylindrical grinding machine, and three coordinates testing machine.

Besides, we have taken various measures to standardize the process flow such as working and cooperating

with many scientific research units, colleges and universities at home and abroad. We also continuously try to

absorb and improve the domestic advanced production technologies, so as to promote the upgrading and

optimization of the product and make the product quality reach the advanced level at home and abroad.

ESR -type Roots Blower includes several series such as Three-leaves Type, Two-leaves Type and Centrifugal

Type,which can be further divided to hundreds of varieties. The products are widely used in sewage treatment,

pneumatic conveying,vacuum packaging, aquaculture, food processing, electric power, petrochemical, cement,

mining and other industries. Our products have such advantages as low noise, energy saving, stable quality,

and long service life, etc.. With the sales outlets throughout the domestic capital cities, our products sell well all

over the country, and have been exported to North America,Russia, Malaysia, Indonesia, Vietnam, South Africa

and some other countries. Having got the ISO9001 International Quality System Certification, we have

established and improved the quality assurance of the products designing, manufacturing, and installation.

From the process of design, research and development to the finished products, we have got the whole

process controlled independently, thus providing the full basis and reliability guarantee for the products stability

and durability. Having a perfect sales network and after-sales service, we provide our customers with higher-

quality and more efficient service.All staff of our company sincerely welcome the broad masses of friends to

guide, and negotiate business with us.

Our Roots Blower Workshop

Doosn Horzitonal Machine Center

The Application of the Roots Blower

Maintenance and inspection

(1) Check all fasteners and locating pins conditions whether they are loosening.

(2) Always check whether the leakage phenomenon of the body.

(3) Pay attention to lubrication, amount of grease and noises when running,

determine whether it works under the required conditions.

(4) Lubricant & grease: The lubricant is for medium load industrial gear oil

(grade 220, kinematic viscosity of 198 ~ 242mm2 / s 40ºC, flash point ≥ 200ºC);

The grease is butter (synthetic lithium grease penetration 220-250, drop point ≥

190ºC). Replace the lubricant and grease after first 200 hours running, and replace

again after a moth running. Later, replace the lubricant and grease according to the

environment and lubricant (grease) quality; propose a suitable replacement for three

months.

(5) Always check the inlet air filter, clean or replace the filter in time.

(6) Blower overload sometimes not immediately displayed, so pay attention to

the intake and exhaust pressure, bearing temperature and the current increase trends

of motor to determine whether the blower works normally;

(7) Before disassembling the blower, the assembling relation and dimensions

must be recorded or measured, make marks on components to ensure the original

requirements after assembling.

(8) When newly machine or overhaul, the oil tank should be cleaned before use

and propose replace all grease after 8 hours running.

Common failure reason and troubleshooting

| No | Failure | Possible reasons | Elimination methods |

| 1 | Friction between the impeller | (1) Impurities on the impeller, resulting in the gap is too small; (2) Gear wear, resulting in a large backlash; (3) The gear is not well fixed, can not maintain the impeller synchronization; (4) Bearing wear resulting in clearance increasing. | (1) Remove dirt and check whether there is damage parts; (2) Adjust the gear gap, replace the gears if the gear backlash is greater than the average 30% to 50%; (3)Re-assemble the gears, keep the taper contact area is to 75%; (4)Replace the bearing |

| 2 | Collision between impeller and wall, the impeller top and casing | (1) Installation gap is not correct; (2) operating pressure is too high, exceeding the specified value; (3) Operating temperature is too high; (4) Casing or base deformation, positioning fan failure; (5) Bearing axial location is not good | (1) Adjust the gap; (2) Identify causes of overloading, reduced the pressure to the specified value; (3) Check the installation accuracy and reduce the pipe tension; (4) Check and repair bearings, and to ensure the clearance (5)Relocation |

| 3 | Temperature too high | (1) Oil in tank is too much, too thick or too dirty; (2) Filter or silencer is blocked; (3)The pressure is higher than the specified value; (4)Excessive wear of the impeller, large gap; (5)Poor ventilation, indoor temperature is high, resulting in inlet air's high temperature; (6) The rotating speed is too low,result in the belt slipping. | (1)Reduce the oil level or rely on oil; (2)Remove of blocking objects; (3)Reducing the pressure through the blower; (4)Repair its clearance; (5)Open vents to reduce room temperature; (6) Increase speed to prevent the belt slipping. |

| 4 | Insufficient flow | (1) The inlet filter is blocked ; (2) Impeller wear and the gap increases too much; (3) Belt slipping; (4) Large imports pressure loss; (5) Pipeline ventilation leakage | (1) Clean the filter dust and obstruction; (2) Repair the gap; (3)Tighten the belt and increase the number of belts; (4)Adjust the inlet pressure to the specified value; (5) Check and repair the pipeline |

| 5 | Oil leaking or oil leaking into the enclosure | (1)High tank position cause leakage from the discharge port; (2) Seal wear, resulting in shaft oil spills; (3) The pressure is higher than the specified value; | (1)Reduce the oil level; (2)Replace the seals; (3)Clear the air vents, 2mm diameter faucet is fixed in the middle chamber, open the faucet under the wall; |

| 6 | Abnormal vibration and noise | (1)Bearing clearance exceeds the specified value or bearing wear; (2) The gear backlash is too large, not in a tight fixed; (3) The foreign objects and dust caused by the impeller and the impeller, the impeller and the housing collision;; (4) the impeller shaft deformation caused the collision caused by overload, (5) Friction between the impeller and the inlet housing caused by overheating; (6) Unbalance of the impeller caused by fouling or foreign body; (7) Anchor bolts or other fasteners are loosened | (1)Replace bearings or bearing seat; (2)Reassemble gear and ensure backlash; (3)Cleaning blower, check the case is damaged; (4)Check the back pressure, check the wheel and adjust gap; (5)Check the filter and back pressure, increase the gap between the impeller inlet and the casing; (6)Clean the impeller and the casing, to ensure that the impeller clearance work; (7) Tighten the anchor bolts and leveling the base. |

| 7 | Motor overload | (1)Compared with the required pressure, the pressure difference is large that the back pressure or the inlet pressure is high; (2) Compared with the equipment requirements, blower flow is too big, so its pressure increases; (3)Inlet filter is blocked, or outlet pipe is obstructed or blocked ; (4) Collusion or friction (stuck) rotating parts; (5) The oil level is too high; (6) Narrow V-belt is overheat, vibration is too large, or pulley is too small | (1) Reduce the pressure to the specified value; (2) Exhaust the excess gas into the atmosphere or reduce the blower speed; (3) Remove the obstructions; (4)Immediately shut down, check the reason; (5) Adjust the oil to the correct level; (6) Check the belt tension, and replaced it with large diameter pulley. |

Our Service

1. Pre sell service 2. After sell service

a. recommend the suitable model c. online technical support,

b. factory tour d. whole life spare parts and techinical support

Gurantee

12 months gurantee for our roots blowers