Fish feed mill machine floating fish feed machine price

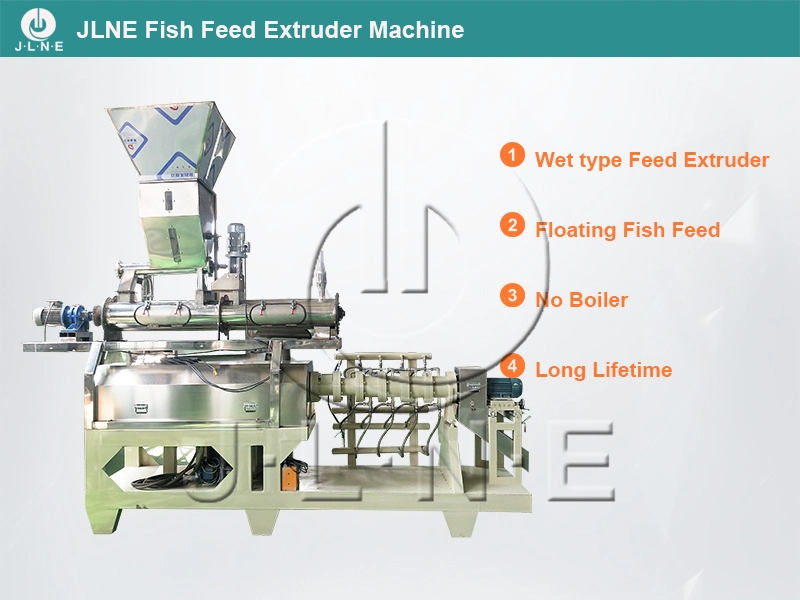

DGP/DSP Fish Feed Mill

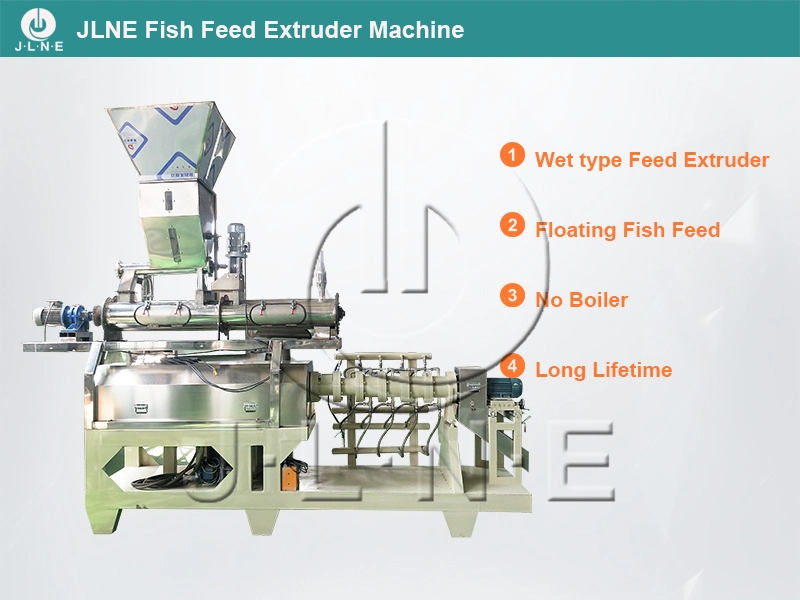

1. This Animal feed mill is wet type extruder, stainless steel, new designed. Usually wet type need boiler to supply steam, our new animal feed mill DO NOT NEED BOILER. It use an eletromegnetic heating system instead of boiler, more efficiency and economic.

2. We adopt the new design of direct connection of motor shaft and he main shaft That overcome the loose defect of belt connecting as long time using.

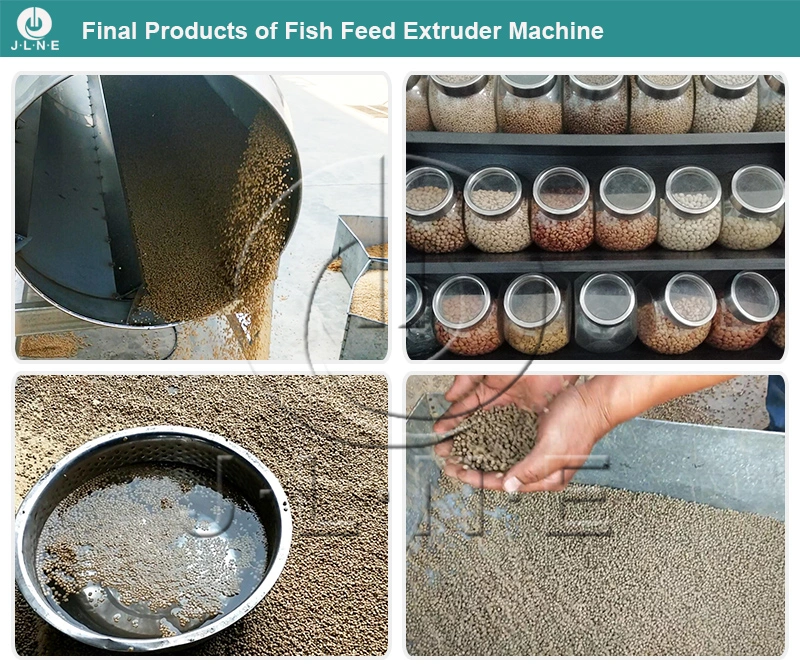

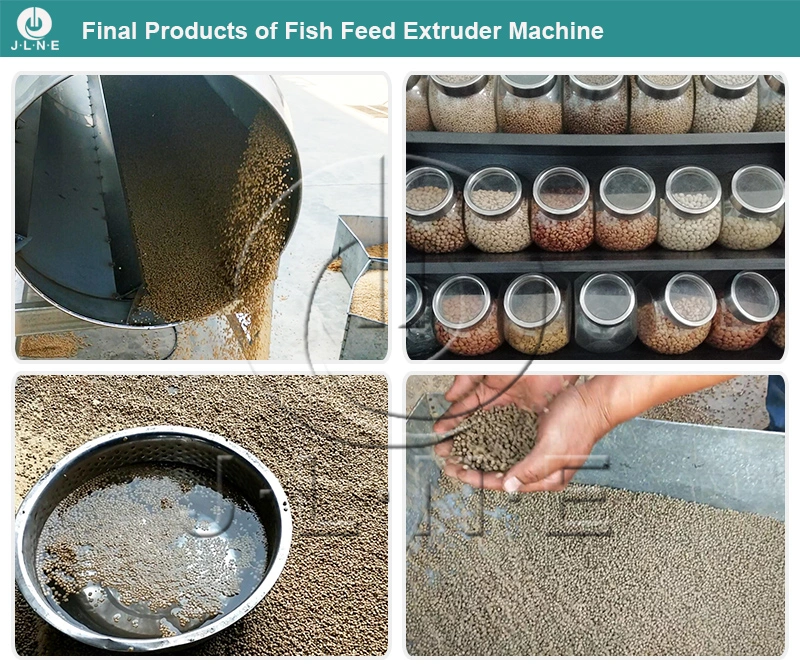

3. When the fodder is added in, the template, pressing roller and fodder will be heated to 60-80 degree by the friction among them.

4. After being pressed through the template, the fodder will be thrown From the machine in a state of granular.

5. You can choose the size of the granules by using different template with different size of holes in it.

6. A diesel engine is another choice to drive the machine, Together with the clutch and accelerating-decelerating device to change its speed.

Raw Materials of Fish Feed Mill

Our floating fish feed pellet extruder is based on the raw material of corn meal, flour, Wheat middling, Wheat bran, rice bran, soybean meal, cottonseed meal, fish meal, bone meal, meat meal and etc. Then the material can be expanded to pellet feed which is different shaped, unique taste and rich nutrition, suitable for dog, cat, fish, bird, rabbit, fox etc.

Advantages of Fish Feed Mill

It can make the fullest use of natural resources, have good rigidity, perfect smoothness, Long shelf life and standard degree of moistness.

Applied Range of Fish Feed Mill

The floating fish feed pellet machine can be used for heat daily or mixed fodder by corn, beans, straw, grass meal, etc materials.

1. Feeding Hopper of the floating fish feed machine: helping receiving and uniform feeding raw materials into the extruder machine

2. Feeding motor: supply power for feeing hopper.

3. Material outlet and extrusion inlet: receiving material and into extrusion room.

4. Extrusion room: the most important part of machine, materials to final products by heating and pressed.

5. Main motor: supply power for main machine and extrusion screws.

6. Cutting motor and cutter: Cutting final products into suit size we needed by adjusting cutters.

Main Data of Fish Feed Mill

Dry type extruder

Wet type extruder

Fish Feed Production Machine Production Lines

Fish Feed Production Machine Spare Parts

DGP/DSP Fish Feed Mill

1. This Animal feed mill is wet type extruder, stainless steel, new designed. Usually wet type need boiler to supply steam, our new animal feed mill DO NOT NEED BOILER. It use an eletromegnetic heating system instead of boiler, more efficiency and economic.

2. We adopt the new design of direct connection of motor shaft and he main shaft That overcome the loose defect of belt connecting as long time using.

3. When the fodder is added in, the template, pressing roller and fodder will be heated to 60-80 degree by the friction among them.

4. After being pressed through the template, the fodder will be thrown From the machine in a state of granular.

5. You can choose the size of the granules by using different template with different size of holes in it.

6. A diesel engine is another choice to drive the machine, Together with the clutch and accelerating-decelerating device to change its speed.

Raw Materials of Fish Feed Mill

Our floating fish feed pellet extruder is based on the raw material of corn meal, flour, Wheat middling, Wheat bran, rice bran, soybean meal, cottonseed meal, fish meal, bone meal, meat meal and etc. Then the material can be expanded to pellet feed which is different shaped, unique taste and rich nutrition, suitable for dog, cat, fish, bird, rabbit, fox etc.

Advantages of Fish Feed Mill

It can make the fullest use of natural resources, have good rigidity, perfect smoothness, Long shelf life and standard degree of moistness.

Applied Range of Fish Feed Mill

The floating fish feed pellet machine can be used for heat daily or mixed fodder by corn, beans, straw, grass meal, etc materials.

1. Feeding Hopper of the floating fish feed machine: helping receiving and uniform feeding raw materials into the extruder machine

2. Feeding motor: supply power for feeing hopper.

3. Material outlet and extrusion inlet: receiving material and into extrusion room.

4. Extrusion room: the most important part of machine, materials to final products by heating and pressed.

5. Main motor: supply power for main machine and extrusion screws.

6. Cutting motor and cutter: Cutting final products into suit size we needed by adjusting cutters.

Main Data of Fish Feed Mill

Dry type extruder

| Model | Power(kw) | Capacity(kg/h) | Cutting Power(kw) | Feeding Power(kw) | Feed Size(mm) |

| DGP-50 | 11 | 60-80 | 0.4 | 0.4 | 1-10 |

| DGP-60 | 15 | 120-150 | 0.4 | 0.4 | 1-10 |

| DGP-70 | 18.5 | 180-250 | 0.4 | 0.4 | 1-10 |

| DGP-80 | 22 | 300-350 | 1.1 | 0.4 | 1-10 |

| DGP-90 | 30/37 | 350-450 | 1.5 | 1.1 | 1-10 |

| DGP-120 | 45 | 500-700 | 2.2 | 1.1 | 1-10 |

| DGP-135 | 75 | 800-1000 | 2.2 | 1.1 | 1-10 |

| DGP-160 | 90 | 1200-1500 | 2.2 | 1.5 | 1-10 |

| DGP-200 | 132 | 1800-2000 | 3.0 | 1.5 | 1-10 |

Wet type extruder

| Model | Power(kw) | Capacity(kg/h) | Cutting Power(kw) | Feeding Power(kw) | Conditioner(kw) |

| DSP-60 | 15 | 180-200 | 0.4 | 0.37 | 0.37 |

| DSP-70 | 18.5 | 200-300 | 0.75 | 0.75 | 1.5 |

| DSP-80 | 22 | 350-450 | 0.75 | 1.1 | 1.5 |

| DSP-90 | 30/37 | 500-700 | 1.1 | 1.1 | 2.2 |

| DSP-120 | 45 | 800-1000 | 1.1 | 1.1 | 2.2 |

| DSP-135 | 75 | 1200-1500 | 2.2 | 1.5 | 2.2 |

| DSP-160 | 90 | 1800-2000 | 2.2 | 2.2 | 3.5 |

| DSP-200 | 132 | 3000-4000 | 3.0 | 2.2 | 4.5 |

Fish Feed Production Machine Production Lines

Fish Feed Production Machine Spare Parts