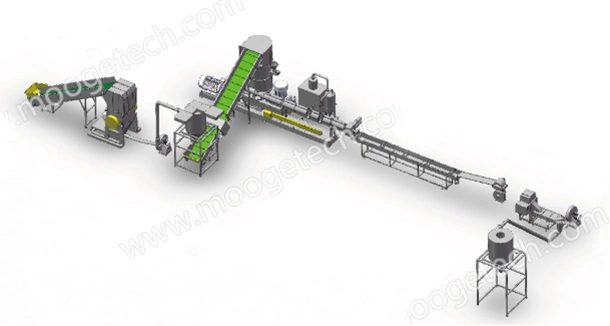

Waste PET Fiber Pelletizing Line

This waste PET fiber pelletizing line is designed and manufactured by MOOGE TECH, which is widely used for clean waste PET fiber, polyester yarn. The material go through crushing, plasticizing, cooling, cutting and collecting system will turn to be perfect pellets for reuse.

This waste PET fiber pelletizing line can be displayed according to clients' workshop.

We can also customize the pelletizing line components according to client's requirement.

Working Flow:

----Belt Conveyor: Feeding material into crusher.

----Crusher: Crushing the PET fiber into small size.

----Cyclone Silo: Temporary store the material and make the material fed evenly in the following step.

----Belt Conveyor: Feeding material into compactor, with metal detector to detect the rock, metal, etc.

----Compactor: With multi blades crushing and compulsively compress the material into extruder.

With side feeder for additive.

----Single Screw Extruder: Melting and Plasticizing material with high temperature, exhausting gas.

----Screen Filter: Filter material impurity to make production more stable.

----Die Mold: Materials come out in long strap.

----Water Tank: Cooling the strap with cold water.

----Air Blower Dryer: Drying the strap.

----Pelletizer Cutter: Cutting the strap into pellets with high rotary speed.

----Vibration Screen: Pick out bigger size pellets and keep good pellets.

----Air Blower: Blow pellets into the silo.

----Storage Silo: Collecting pellets.

----Control Cabinet: Control the line on/off (famous brand such as Schneider, Siemens, etc.)

Technical Parameter:

Features:

1. Automatically working, conveying material, crushing, plasticizing, cooling, drying, cutting, and collecting.

2. High efficiency, safety control, Saving labor cost, capacity from 200-1000 kg/hr.

Transportation and Packing

Our service:

• Pre-sale: we give our client the detailed technician offer, sign the sales contract etc.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours service line to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

•We always update the new technology to every customer

In order to match your requirement and provide you a proper quotation, please advise:

• What material do you want to recycling?

• What capacity(kg/h) do you want?

• What is the final size(mm) of granules you want?

• Other special requirements about the waste PET fiber pelletizing line you want.

If you are interested in our waste PET fiber pelletizing line, pls do not hesitate to contact me!

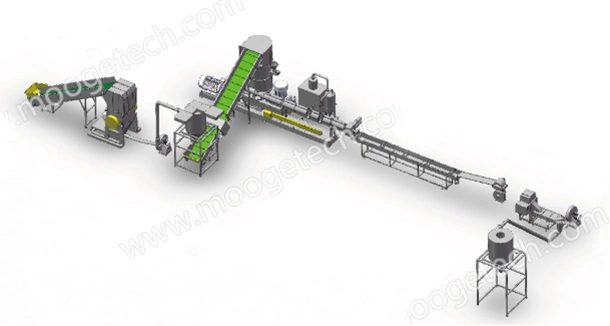

This waste PET fiber pelletizing line is designed and manufactured by MOOGE TECH, which is widely used for clean waste PET fiber, polyester yarn. The material go through crushing, plasticizing, cooling, cutting and collecting system will turn to be perfect pellets for reuse.

This waste PET fiber pelletizing line can be displayed according to clients' workshop.

We can also customize the pelletizing line components according to client's requirement.

Working Flow:

----Belt Conveyor: Feeding material into crusher.

----Crusher: Crushing the PET fiber into small size.

----Cyclone Silo: Temporary store the material and make the material fed evenly in the following step.

----Belt Conveyor: Feeding material into compactor, with metal detector to detect the rock, metal, etc.

----Compactor: With multi blades crushing and compulsively compress the material into extruder.

With side feeder for additive.

----Single Screw Extruder: Melting and Plasticizing material with high temperature, exhausting gas.

----Screen Filter: Filter material impurity to make production more stable.

----Die Mold: Materials come out in long strap.

----Water Tank: Cooling the strap with cold water.

----Air Blower Dryer: Drying the strap.

----Pelletizer Cutter: Cutting the strap into pellets with high rotary speed.

----Vibration Screen: Pick out bigger size pellets and keep good pellets.

----Air Blower: Blow pellets into the silo.

----Storage Silo: Collecting pellets.

----Control Cabinet: Control the line on/off (famous brand such as Schneider, Siemens, etc.)

Technical Parameter:

| Model | Screw Diameter | Screw L/D | Main Motor Power | Capacity |

| PSF-SJ100 | 100mm | 25-35:1 | 75KW | 200-300kg/hr |

| PSF-SJ130 | 130mm | 25-35:1 | 90-110KW | 300-400kg/hr |

| PSF-SJ150 | 150mm | 25-35:1 | 110-132KW | 400-500kg/hr |

| PSF-SJ160 | 160mm | 25-35:1 | 132-160KW | 600-800kg/hr |

| PSF-SJ180 | 180mm | 25-35:1 | 160-200KW | 800-1000kg/hr |

| PSF-SJ200 | 200mm | 25-35:1 | 185-225KW | -- |

Features:

1. Automatically working, conveying material, crushing, plasticizing, cooling, drying, cutting, and collecting.

2. High efficiency, safety control, Saving labor cost, capacity from 200-1000 kg/hr.

Transportation and Packing

Our service:

• Pre-sale: we give our client the detailed technician offer, sign the sales contract etc.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours service line to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

•We always update the new technology to every customer

In order to match your requirement and provide you a proper quotation, please advise:

• What material do you want to recycling?

• What capacity(kg/h) do you want?

• What is the final size(mm) of granules you want?

• Other special requirements about the waste PET fiber pelletizing line you want.

If you are interested in our waste PET fiber pelletizing line, pls do not hesitate to contact me!