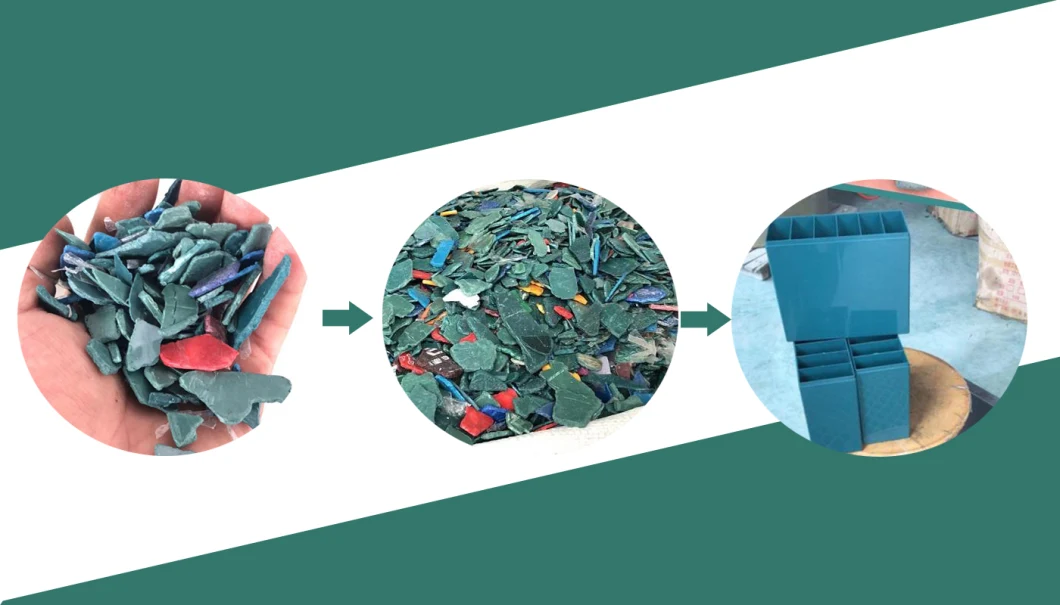

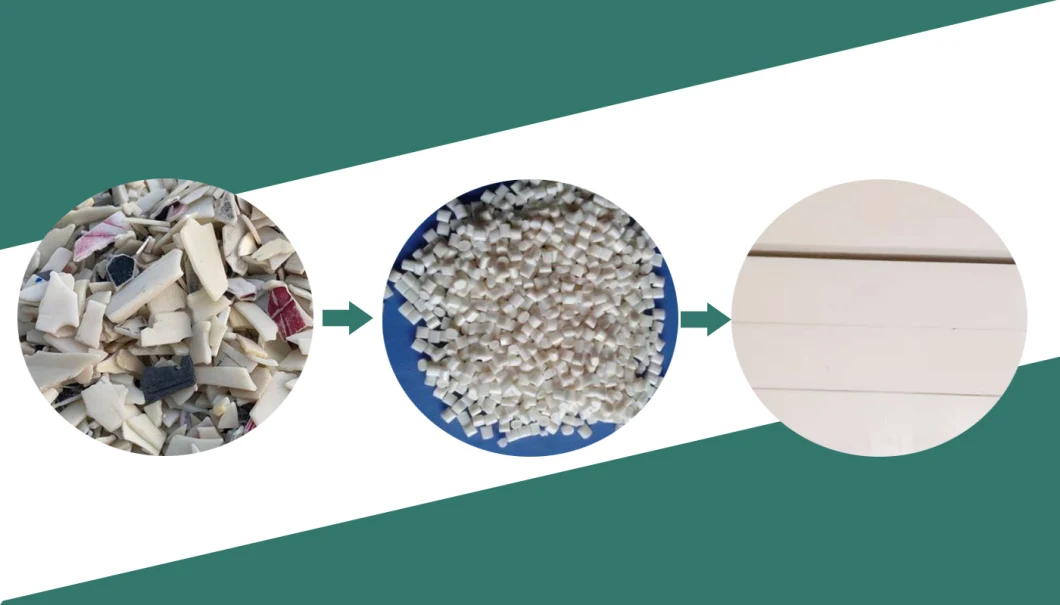

The product is suitable for the production of ABS,PP,PC,PS,POM,PA and other types of engineering modified recycled plastic granulation,

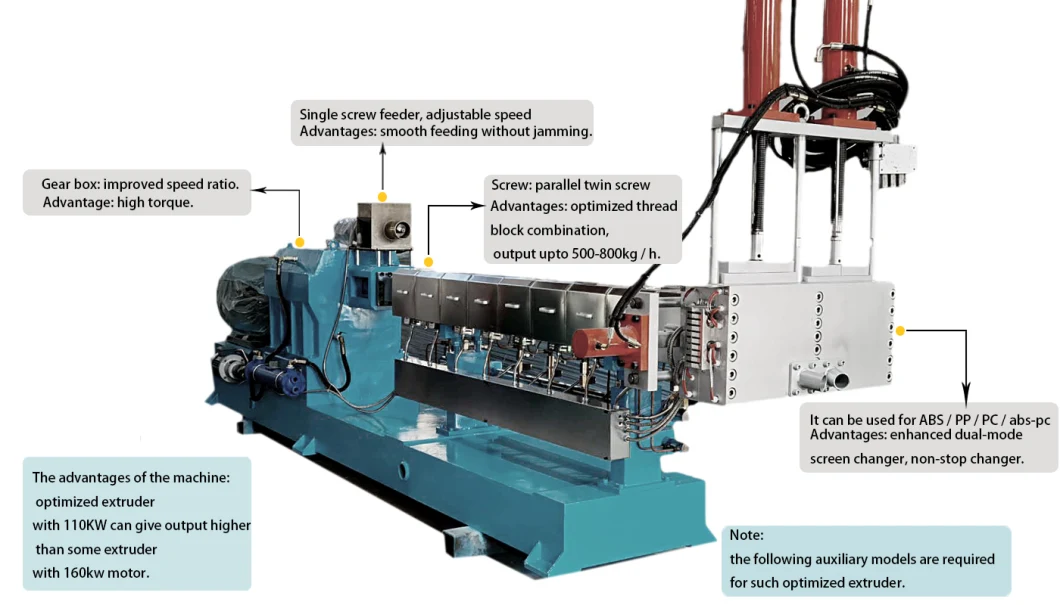

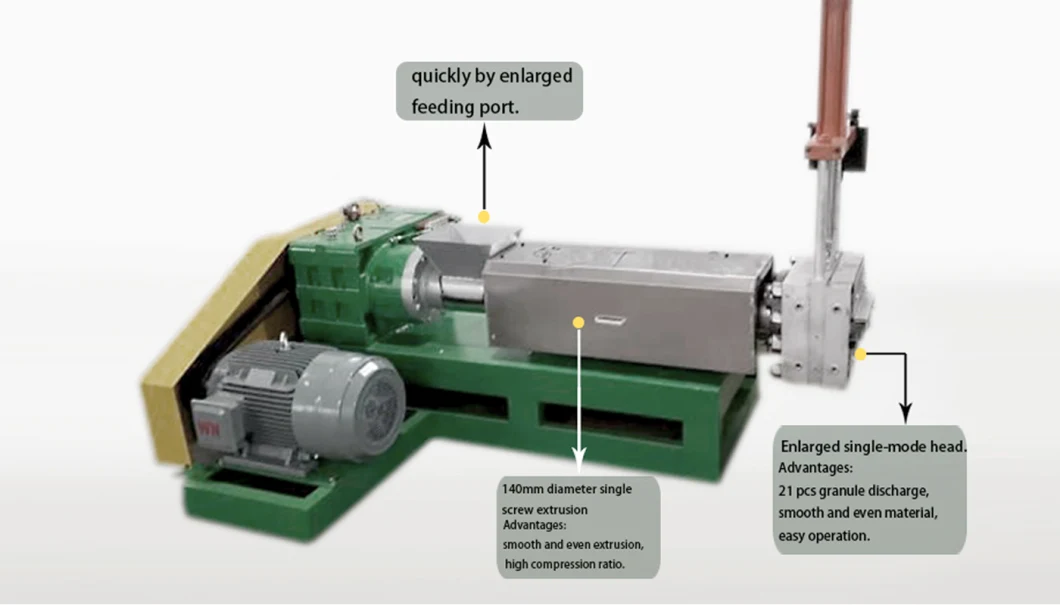

Adopt double stage granulation: first stage with parallel screw extruder and second stage with single screw extruder. The first stage die head with enhanced double screen changer, the second stage with enhance single changer, thus to ensure that the filter screen is replaced during production without stopping the machine. The device provides uniform cutting and saves labor. High-quality electrical and drive equipment make machinery and equipment safer and more reliable in use. This type of equipment drive transmission system is independently designed and improved by our company, with low energy consumption and high output.

Representative Materials Working Capability Schedule Of QX-series

Same-direction Parallel Parallel Twin screw Extruder (Reference Value)

| QX - series twin - screw extruder | 35 | 50 | 65 | 75 | 90 | |

| Process | Representative materials | Operating capability kg/h( reference values) | ||||

| Mixing nature - changing | PE , PP , PS + SBS : PA + EPDM : PP + NBR : EVA + Silicon rubber . etc . | 30-80 | 100 -180 | 160-280 | 350-500 | 700-1100 |

| PE . PA . PC , CPE + ABS ( alloy ) : ABS + TPU : PBT + PET : PP + PE , eto | 25-60 | 80-180 | 160-250 | 300-400 | 600-1000 | |

| Filling nature - changing | PE . PP . EVA , etc . + Calcium carbonate , talcum powder , titanic powder ; ABS , PC : PS . etc , + aluminum hydroxide , magnesium hydroxide , antimony oxide . | 30-60 | 100-200 | 200-400 | 300-550 | 700-1000 |

| PP . PA : ABS + ferrous powder . sulphuric powder . ceramic powder . | 50-90 | 120-250 | 250-400 | 400-600 | 900-1200 | |

| Functional machine pellets | PP . PA . ABS . PBTetc + anti - burning agent and other auxiliary agents : combustion - supporting machine pellets . | 30-60 | 100-180 | 200-300 | 350-450 | 800-1100 |

| PE . PP . PS . etc + starch : de - composing machine pellets | 30-50 | 90-150 | 150-200 | 200-350 | 600-800 | |

| PE + fog - preventing dipper , stabilizer : dual - prevention machine pellets | 30-50 | 70-100 | 170-220 | 250-350 | 600-750 | |

| PE . EVA . ABS . etc + carbon black : black machine pellets | 20-40 | 50-100 | 150-220 | 220-320 | 400-700 | |

| Colored machine pellets | PE . PP . ABS . AS . PA . EVA . PET + pigment and auxiliary . | 30-50 | 80-150 | 150-250 | 250-350 | 500-750 |

| Intensified glass fibres and carbon fibres | PP . PBT . ABS . AS . PA , PC . POM , PPS , PET . etc . + long fires , small fibres , carbon fibres . crystals and so on , etc . | 30-80 | 100-180 | 180-300 | 250-450 | 550-900 |

| Various cables | HDPE , LDPE . LLDPE , MDPE . EVA . PVC . PP , etc , insulating cables , coatings : PE peroxide , silicon alkyl crossing cables : radialization crossing cables . | 20-80 | 80-180 | 150-300 | 250-450 | 500-900 |

| Special materials | EVA heat - melting glue , polyurethane , fluorin rubber , fluorine plastics , PP cigarette filtering material and TPR sole material | 20-100 | 40-200 | 100-350 | 150-500 | 450-1100 |

| Reaction extruding | Polyamide condensate , polyamide melting polymerization , polyamide polyethene - adding , polycarbonate condensate , etc . | 15-35 | 80-150 | 180-250 | 250-400 | 450-700 |

| Exhausting and volatilization | Polystyrene oxide , high - absorbing resin , chlorine sulphur polyethylene | 10-40 | 50-100 | 80-200 | 120-300 | 200-500 |

Powder paint | Polyester , ring oxide , lactide , polyurethane , acrylate | 80-120 | 180-280 | 350-480 | 600-780 | 1200-1400 |