Keywords:

plastic pelletizing machine

PE film granulator

PE PP granulating machine

PE/PP pelletizing line

****************************************************************************

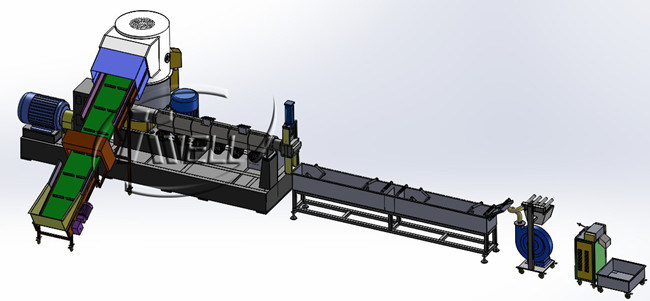

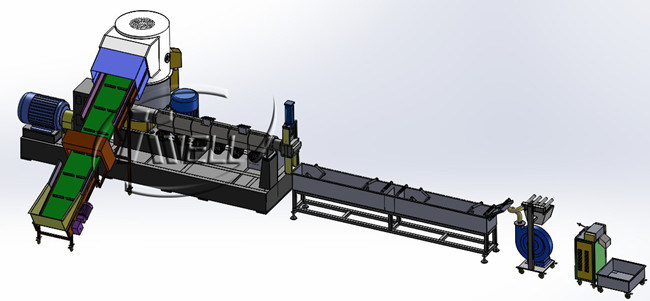

PE/PP Film Compactor Pelletizer/water ring granulator pelletizer line machine

Machine Application:

This PE film granulator machine can be used to recycle PE, HDPE, LDPE, PP, BOPP, etc

Material shapes: film, bag, (PE, PP) regrind

Material types: rolls, loose, bundled

Material comes from off-cut, industry defective film, washed film and printed film.

Note: depending on different material properties, various downstream equipments are needed.

Machine composition:

Compacting---Extrusion---Pelletizing: 3-in-1

Extruder type: One Stage; Two Stage (mother and baby)

Pelletizing type: Hot Die face Water ring pelletizing; Strand Noodle pelletizing

Machine Parameter for Reference:

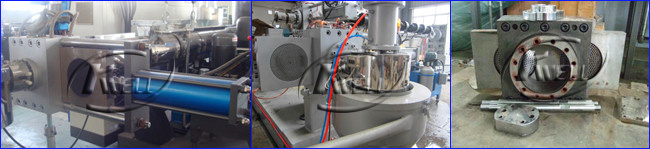

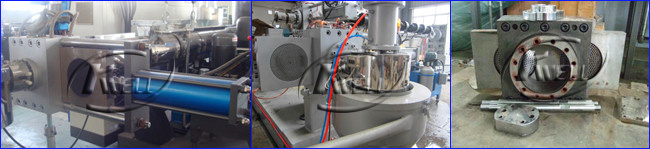

Machine Detail photos :

Machine Packing Details:

After-sale:

1. Provide with installation, commissioning and training

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

Why choose us:

1. Lower investment cost for a high quality and durable machine;

2. Low energy consumption with high production output;

3. Overseas installation and training are available;

4. Machine warranty with spares in stocking and in-time delivery;

5. Fast machine delivery and installation: KWELL produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an KWELL recycling machine is 30 days.

Please convenient yourselves by me !!

http://kwellgroup.en.made-in-china.com/

plastic pelletizing machine

PE film granulator

PE PP granulating machine

PE/PP pelletizing line

****************************************************************************

PE/PP Film Compactor Pelletizer/water ring granulator pelletizer line machine

Machine Application:

This PE film granulator machine can be used to recycle PE, HDPE, LDPE, PP, BOPP, etc

Material shapes: film, bag, (PE, PP) regrind

Material types: rolls, loose, bundled

Material comes from off-cut, industry defective film, washed film and printed film.

Note: depending on different material properties, various downstream equipments are needed.

Machine composition:

Compacting---Extrusion---Pelletizing: 3-in-1

Extruder type: One Stage; Two Stage (mother and baby)

Pelletizing type: Hot Die face Water ring pelletizing; Strand Noodle pelletizing

Machine Parameter for Reference:

| Extruder model | Compactor Power(kw) | Extruder Power(kw) | Capacity(kg/hr) |

| SJ85 | 37 | 55 | 180-250 |

| SJ100 | 55 | 90 | 250-300 |

| SJ120 | 75 | 110 | 300-400 |

| SJ130 | 90 | 132 | 400-500 |

| SJ150 | 90 | 160 | 500-600 |

| SJ160 | 110 | 185 | 600-700 |

| SJ180 | 160 | 250 | 800-1000 |

Machine Detail photos :

Machine Packing Details:

After-sale:

1. Provide with installation, commissioning and training

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

Why choose us:

1. Lower investment cost for a high quality and durable machine;

2. Low energy consumption with high production output;

3. Overseas installation and training are available;

4. Machine warranty with spares in stocking and in-time delivery;

5. Fast machine delivery and installation: KWELL produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an KWELL recycling machine is 30 days.

Please convenient yourselves by me !!

http://kwellgroup.en.made-in-china.com/