| Purpose | Raw Materials | ||||

| Filling & Modification | PE,PP,PS,EVA+CaCo3,Talcum Powder,TiO2 | ||||

| PP,PA6,PA66,ABS+Ferrous Powder,Magnetic Powder,Ceramic Powder | |||||

| Blending & Modification | PP,PA,PE+EPDM;PE,PP,PS+SBS;PP+NBR;EVA+Silastic;TPR compounds | ||||

| PP+PE;PBT+PET;PA,,PC,CPE,TPU+ABS | |||||

| Masterbatch | PE,PP,PS,ABS,EVA,PET+Pigment and additives | ||||

| Functional Masterbatch | CB masterbatch: PE,PP,PS,ABS,EVA+carbon | ||||

| Flame retardant masterbatch: PE,ABS,PA PBT+flame retardant&additives | |||||

| Degradative masterbatch: PE,PS+Starch;PP+CaCO3,Talcum powder | |||||

| Safeguard function masterbatch:Masterbatch of heat insulator | |||||

Glass Fiber(carbon fiber,wood fiber) Reinforcement | PE,ABS,AS,PBT,PET,PA,PC,PPS+Carbon fiber | ||||

| PP,ABS,AS,PBT,PET,PA,PC,PPS,PPO+long glass fiber or shot glass fiber | |||||

| Various Cable Material | HDPE, LDPE, LLDPE, MDPE insulating bush, cable shield | ||||

PE Six-XLPE cable compounds,PE chemical crosslink cable compounds, PE radiation crosslinking cable compounds,H-cable compounds | |||||

| PVC wire&cable compounds | |||||

| HFFR,Polyolefine cable compounds | |||||

| Powder Coating | Polyester coating,Polyurethane coating,epoxy resin coating,Propyl coating; Pcrylic coating | ||||

| Heat-Sensitive Material (Cascade type) | PVC wire&cable compounds, Undersole compounds | ||||

| Flexible/Rigid-PVC compounds and Semerigid compounds etc. | |||||

Non-toxic transparent PVC-bottle material, Perfusion-tube material,Blood transfusion-haustrum material | |||||

| Low-smoking&non-halogen flame-retardant wire&cable compounds, PE cross-linking/peroxide crosslinking compounds | |||||

Dynamic state cross-linking thermoplastic-elastomer compounds,Radiating cross-liking wire&cable compounds plastic filler or color masterbatch machine

| |||||

The date of the machine

| Mode | Screw Diameter D(mm) | Screw Length(mm) | L/D | Screw Rater N(r/min) | Motor Power P(kw) | Torque T(N.m) | Torque Level T/N3 | Capacity Q(kg/h) | Weight(kg) | Dimension (m) |

| SHJ-20 | 22 | 150 | 32-44 | 600 | 5.5 | 43 | 7.5 | 0.5-10 | 1000 | 1.7*0.5*1.8 |

| TSE-30A | 31 | 32-48 | 500 | 11 | 105 | 5.9 | 5-30 | 1500 | 2.4*0.63*2 | |

| TSE-30B | 600 | 15 | 119 | 6.7 | 5-40 | |||||

| SHJ-35A | 35.6 | 32-48 | 600 | 15 | 119 | 4.4 | 20-60 | |||

| TSE-40A | 41 | 160 | 32-64 | 400 | 22 | 263 | 6.4 | 65-110 | 3000 | 2.9*0.65*2 |

| TSE-40B | 41 | 160 | 32-52 | 600 | 30 | 239 | 5.8 | 90-150 | ||

| SHJ-50A | 50.5 | 32-52 | 500 | 45 | 430 | 5.4 | 135-225 | |||

| TSE-52B | 51.5 | 210 | 32-64 | 600 | 55 | 438 | 5.5 | 225-250 | 3000 | 3.8*2*0.69 |

| TSE-52C | 51.5 | 210 | 32-64 | 600 | 75 | 597 | 7.5 | 200-300 | ||

| SHJ-65A | 62.4 | 240 | 32-52 | 400 | 75 | 895 | 6.3 | 180-250 | 4000 | 4.2*0.67*2.2 |

| 500 | 75 | 716 | 5.1 | 180-250 | ||||||

| TSE-65B | 62.4 | 240 | 32-64 | 600 | 90 | 716 | 5.1 | 200-300 | ||

| SHJ-75A | 71 | 290 | 32-56 | 400 | 90 | 1074 | 5.0 | 225-350 | 4000 | 4.8*0.78*2.3 |

| 500 | 110 | 1050 | 4.8 | 250-450 | ||||||

| TSE-75B | 71 | 290 | 32-64 | 600 | 132 | 1050 | 4.8 | 350-550 | ||

| TSE-75D | 71 | 290 | 32-64 | 60O | 220-250 | 1990 | 9.2 | 500-1000 | ||

| TSE-95A | 93 | 360 | 32-64 | 500 | 250 | 2387 | 5.0 | 600-1000 | 4000 | 6.2*0.87*2.4 |

| TSE-95B | 93 | 360 | 32-64 | 600 | 315 | 2506 | 5.3 | 800-1200 | ||

| TSE-135A | 133 | 32-64 | 500 | 750 | 7162 | 5.38 | 1500-2250 | 4000 |

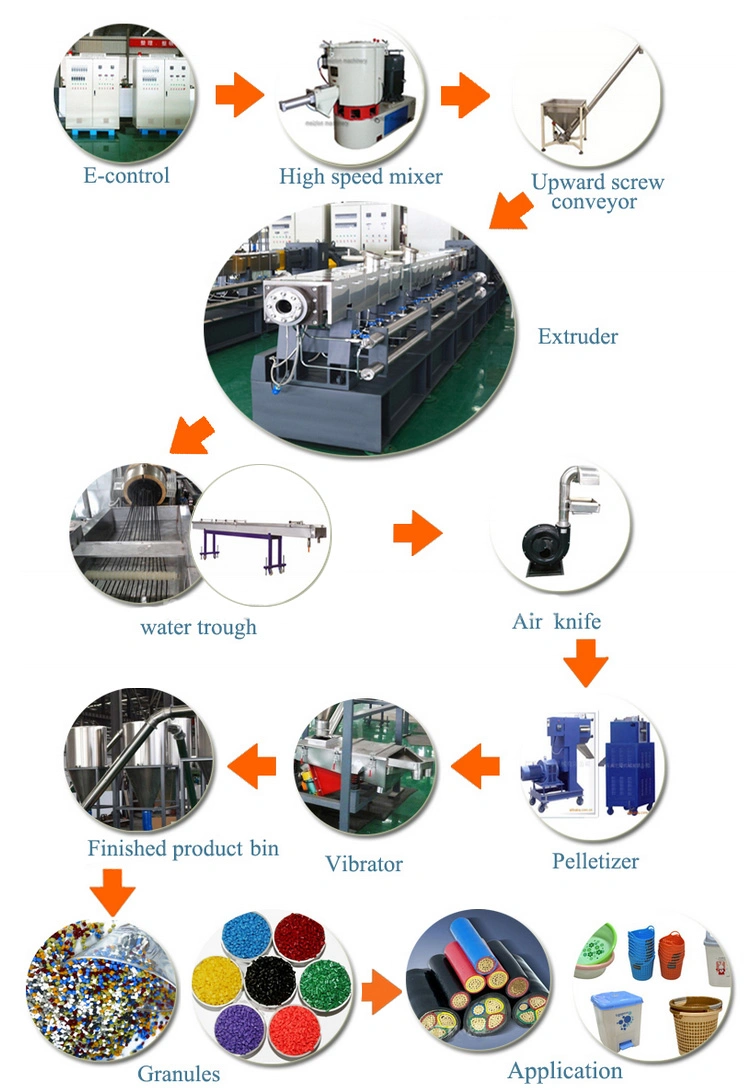

Detail show of extruder and pelletizer

The application of the machine

The application of the machine

Elastomer TPU, TPE,TPO,POE,EVA,SBS

Thermo-plastic PE, PP, PS, PA modified

Low viscosity reaction polymer, all kinds of hot-melt adhesive

Pure polymer

Extensive heat and mass transfer, narrow residence time distribution, large surface to volume

ratio, continuous operatio. Ideal for high viscosity, high temperature reaction systems.Conti-

nuous polymerization or reactive extrusion like dynamic vulcanization, cross linking, grafting,

and chain extension of PP, TPU, TPE, TPV, PUR, PA, POM, PEI, PC, PMMA, PBT, PPS, etc.

KR-Mach is a leading plastic and rubber machinery supplier.

Our products includ:

1 Plastic Extrusion Pelletizing Machines

2 PP PE+caco3 filler masterbatch

3 Plastic Recycling Machines

4 color masterbatch machine

Over the years we have supply the world market, like USA UK FRANCE RUSSIA TURKEY SOUTH ASIA MIDDLE EAST

SOUTH AMERICA all kinds , all kinds of plastic and rubber machines.

Our service

Before sales

Our company

Kairong group , headquartered in Nanjing, China, is a global manufacturing and trading company in the field of highperformance plastics and rubber processing equipment , extrusion solutions, masterbatch and compounding, etc. Its unit Nanjing Haisi Extrusion Company is a prefessional manufacturer of twin screw extruder, single screw extruder ,two stage extruder and its related auxiaries. We tailor solutions from raw materials, materials processing equipment, to injection for different customers. Each Kairong solution is designed , manufactured, and commissioned by experienced teams of professionals engineers and aftersales staffs.